CIMC tanker: Guarding the line of the hazardous chemicals transportation market!

Date:2024-06-14 Author:Sissi Source:www.chinaspv.com

In 2023, China's petroleum and chemical industry achieved operating income of nearly 16 trillion yuan, a year-on-year decrease of 1.1%, and total industry profits of 873.3 billion yuan, a year-on-year decrease of 20.5%. Under the condition of substantial growth in the production capacity of the chemical industry, the operating income and industry profits of the chemical industry have not increased but decreased, reflecting the severe challenges faced by the industry. As the link between the chemical industry and the market, the safety, greenness, efficiency and innovation of chemical logistics are of great significance to promoting the sustainable development of the entire industry.

The safe operation of chemical logistics is still the top priority at present. According to statistics, there were 280 road safety accidents involving hazardous chemicals in my country in 2023, a decrease of 10.3% compared with the same period in 2022. Despite the positive progress, the safe operation of chemical logistics still faces severe and complex challenges.

At present, in the domestic market for hazardous chemical transportation equipment, a few mid- and low-end brand manufacturers ignore safety standards and safety regulations, and impact the market with transportation vehicles with backward technology and poor quality. Bad money drives out good money, which buries great hidden dangers for the safe operation of chemical logistics.

Recently, at the 288th kilometer of Gaomiaozi Village, Xinghe County, Ulanqab City, Inner Mongolia, a tank truck loaded with methanol overturned and leaked liquid due to braking on a downhill section.

Recently, a hazardous chemical transport truck carrying 30 tons of methanol was involved in a rear-end collision in Huainan City, Anhui Province. After on-site investigation, the front of the transport truck was seriously damaged, and the left side of the front of the tank was hit (Ruijiang tank), but it was only slightly deformed, and no methanol leakage occurred, which won time for the subsequent safe handling of the dangerous situation.

Faced with the trend of intensified industry competition, the technological upgrading of chemical logistics equipment is urgent. As a global leading brand of tank vehicles, CIMC tanker adheres to safety standards and accurate identification and compliance with safety regulations, takes it as its mission to promote the healthy development of the industry, takes cutting-edge technology as its focus, establishes a European Research Institute, carries out "China-Europe Interaction" technology synchronization, and jointly with the Ministry of Transport, participates in the formulation of industry standards, promotes innovation and iteration of the chemical logistics equipment industry, protects inherent safety, and guards the last bottom line of the hazardous chemicals transportation market!

In the whole series of CIMC tanker's new generation of hazardous chemical tank trucks, the consideration of "safety" is everywhere, directly hitting the safety pain points of the industry, and five innovative technologies to escort the transportation of hazardous chemicals.

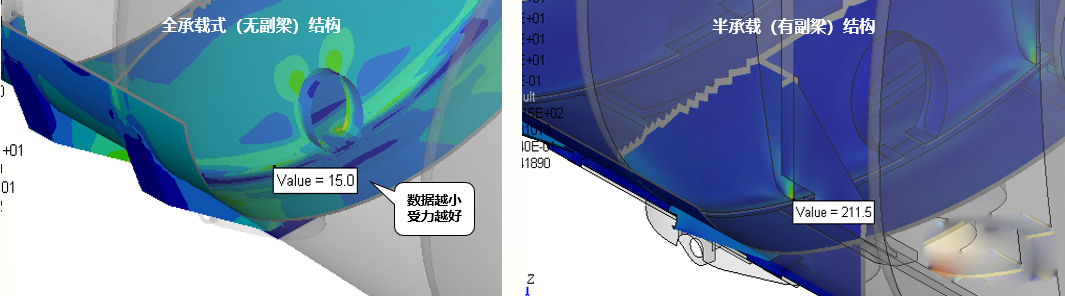

1. The frame is a full-load-type frame structure without a sub-beam, which "protects" the tank body in all directions

CIMC tanker has fully introduced European technology, combined with domestic road optimization, and adopted a full-load-type frame structure without a sub-beam, which greatly reduces the stress of the tank body and completely solves the cracking problem of the tank body and its accessories.

Stress comparison of full/semi-loaded tank

Fully load-bearing frame structure without sub-beam

Integrated coordinated braking technology for main suspension, no fear of rollover and tail swing, making driving more confident

CIMC tanker has cooperated with domestic mainstream OEMs to carry out integrated technology research and development interaction, realizing main suspension joint braking, shortening the braking distance by 10%; main suspension braking force distribution, avoiding head-on and tail swing; equipped with body stability control ESC system, greatly improving vehicle driving stability.

Integrated coordinated braking for main suspension

Three-level anti-collision technology at the rear of the tank body, making rear-end collision accidents "smaller"

Based on a large number of rear-end collision accident analysis and experimental data comparison, CIMC tanker pioneered the industry's first three-level protection design for the rear of the tank body, which fully protects the rear tank body and the rear valve, and forms a standard configuration on its entire series of dangerous goods tank trucks.

Level 1 protection: The high-strength steel rear bumper and the buffer distance far exceeding the national standard provide the primary protection when the tank truck is rear-ended; Level 2 protection: The unique I-beam structure provides sufficient rigidity for the frame to form a secondary protection to deal with major rear impacts; Level 3 protection: The tank body and the bracket are connected by assembled bolts to effectively absorb the extreme collision energy, achieve the effect of unloading, and prevent the tank body from being torn.

In addition, the rear anti-collision warning system is matched, and the 70m rear vehicle warning prompt and the reversing obstacle avoidance prompt are used to minimize the probability of collision.

Level 3 anti-collision technology

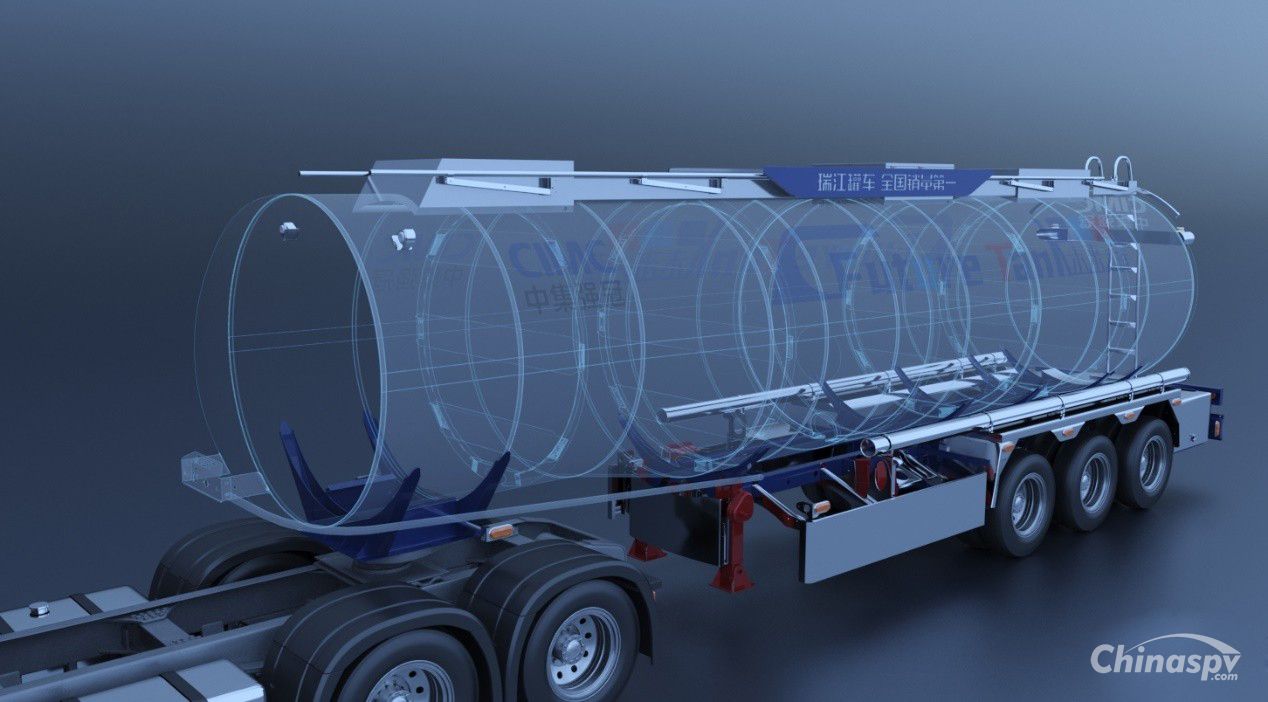

Internal and external reinforcement structure technology of the tank body, anti-collision, anti-torsion, and anti-squeezing

During the transportation of hazardous chemicals, due to factors such as transportation vibration and liquid sloshing, the tank body with insufficient rigidity will undergo slight deformation. This slight deformation is difficult to detect, but it is extremely harmful. Long-term accumulation will cause the risk of tank cracking and liquid leakage. CIMC tanker uses internal and external reinforcement structure technology of the tank body that meets regulatory requirements to greatly improve the overall rigidity of the tank body, with the overall strength increased by 1.2 times, torsional rigidity increased by 1.6 times, and negative pressure resistance increased by 1.8 times

Tanker body external protection: 7 "Ω"-shaped tank body external reinforcement ring structures are like wearing a safety helmet for the tank body. When the vehicle rolls over or is scratched, it plays a role in buffering and reducing friction for the tank body;

Tanker body internal protection: According to the difference in tank body volume, differentiated internal reinforcement rings and wave-breaking plate structures are designed to effectively avoid the risk of sudden changes in the structure puncturing the tank body when the tank body is squeezed.

Structural design of inner and outer reinforcement rings of the tank

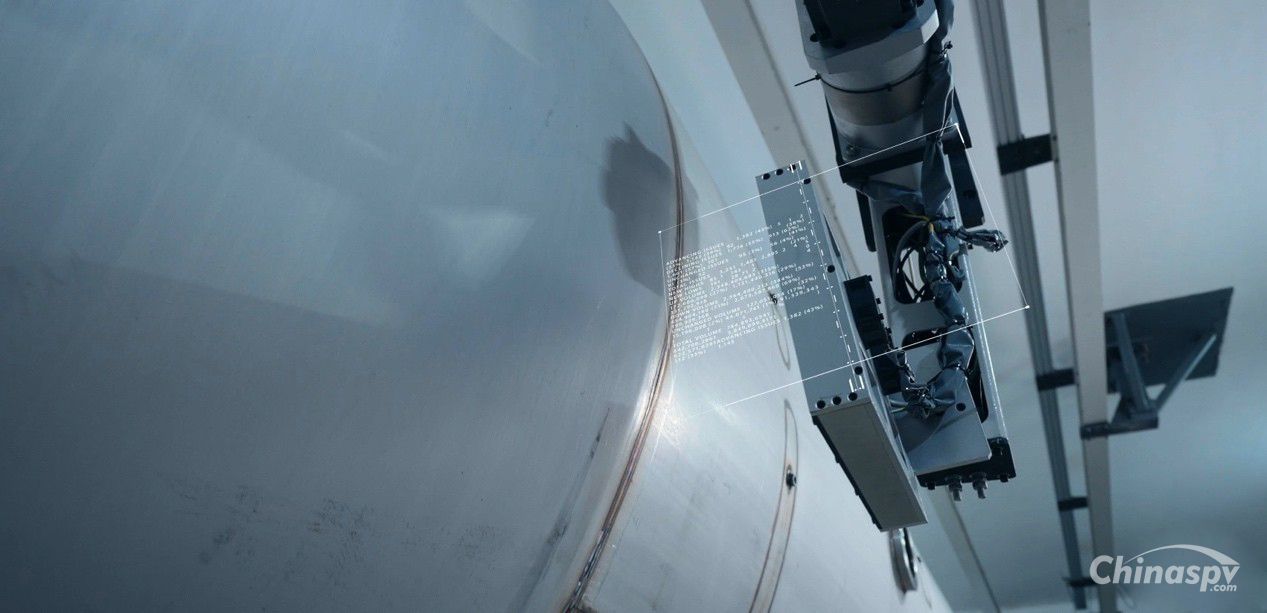

V. DR digital flaw detection technology, 100% qualified, no fear of leakage

The core of ensuring that the tank does not leak is the quality of the weld. How to judge the quality of the weld is good, both the surface and the core should be looked at. Through DR digital radiographic flaw detection technology, digital imaging and digital analysis, the quality of the cylinder weld is 100% qualified, leaving no room for defects.

DR digital radiographic flaw detection technology

In the future, CIMC tanker will always adhere to innovation-driven, adhere to the social responsibility of safe transportation, give full play to its own advantages, and continue to create value for customers in the research and development, innovation and multi-scenario application of hazardous chemical transport tankers, and help ensure the safe and efficient operation of the chemical logistics supply chain.

Views:2759